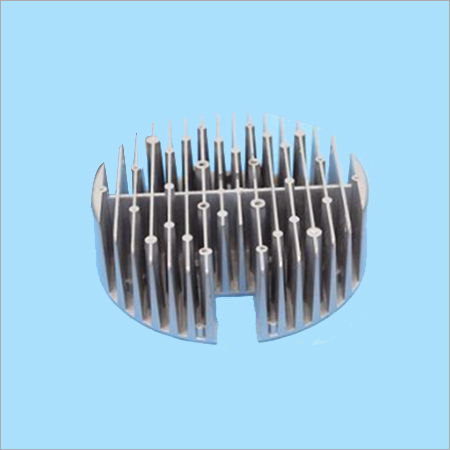

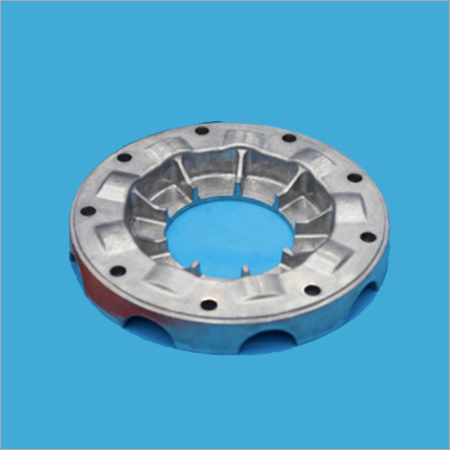

Industrial Component Aluminium Pressure Die Casting

Industrial Component Aluminium Pressure Die Casting Specification

- Material

- Aluminium

- Application

- Industrial Component Manufacturing, Automotive, Machinery Parts

- Processing

- Pressure Die Casting

- Surface

- Smooth Finish, As Cast or Custom Surface Treatment

- Machining Type

- CNC Machining, Traditional Machining

- Typical Standards

- ISO 9001, DIN 1725, ASTM B85

- Casting Tolerance

- Up to ±0.05 mm

- Minimum Wall Thickness

- 2 mm

- Production Capacity

- Up to 100,000 units per month

- Finish Options

- Powder Coating, Anodizing, Polishing

- Dimension Range

- Custom, up to 500 mm

- Weight Range

- 10 grams to 5 kilograms

- Mould Type

- Permanent Steel Die

- Corrosion Resistance

- High

- Hardness

- Brinell 50-70 HB

- Shape Complexity

- High (complex geometries achievable)

Industrial Component Aluminium Pressure Die Casting Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 2 Pieces Per Day

- Delivery Time

- 2 - 10 Days

About Industrial Component Aluminium Pressure Die Casting

Versatile Applications and Usage

Industrial Component Aluminium Pressure Die Casting components offer superb adaptability for automotive, machinery, and general industrial manufacturing. Suitable for both specific and general use, these parts deliver reliability in critical equipment and assemblies. With custom dimension options and high complexity available, they enhance value in prototyping, mass production, and OEM applications. Whether integrated in engines, enclosures, or machined assemblies, their robustness and corrosion resistance make them a go-to choice for vigorous usage.

Payment, Shipping and Certification Information

Sale price and shipping estimates are tailored to your order specifications, ensuring competitive value. We operate through trusted FOB ports across India for global shipment, simplifying logistics for every client. Secure transactions are available via multiple payment terms, including advance and letter of credit options. Each batch is backed by certifications like ISO 9001, guaranteeing compliance and quality you can trust. Experience smooth transactions and timely deliveries on every shipment.

FAQs of Industrial Component Aluminium Pressure Die Casting:

Q: How is the aluminium pressure die casting process carried out?

A: The process involves injecting molten aluminium into a permanent steel die under high pressure, creating components with superb dimensional accuracy and intricate shapes. After solidification, the casting is released, then further refined through CNC or traditional machining and surface treatments as required.Q: What are the main applications for these aluminium die cast components?

A: These components are widely used in the automotive, machinery, and general industrial sectorsserving as engine parts, housings, structural components, and other custom industrial items where high strength and corrosion resistance are essential.Q: When can I expect shipment after placing an order?

A: Shipment timelines depend on the order quantity and complexity, but most orders are processed and ready for FOB shipment in a mutually agreed timeframe, typically within a few weeks after order confirmation and payment processing.Q: Where are these die cast components manufactured and exported from?

A: All aluminium pressure die castings are manufactured in India, leveraging advanced facilities for export and domestic supply. As an experienced exporter and supplier, global shipment arrangements are efficiently managed from major Indian ports.Q: What benefits do powder coating, anodizing, and polishing offer as finish options?

A: These finish options provide enhanced lustre, greater corrosion resistance, and a smooth, attractive surface. They can be tailored for functional durability or aesthetic appeal, adding value for end-use applications.Q: How is quality assured in the die cast components?

A: Quality is ensured through rigorous adherence to ISO 9001, DIN 1725, and ASTM B85 standards, along with comprehensive inspections at each production stage. Certifications accompany every shipment to validate compliance and performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Die Casting Category

Aluminium Gravity Die Casting

Price Range 200.00 - 500.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Aluminum

Aluminium Automotive Die Casting

Price Range 200.00 - 500.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, Aluminium

Processing : Die Casting

Application : Automotive Components

Surface : Other, Smooth / Polished

Aluminium Pressure Die Casting

Price Range 200.00 - 500.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, Aluminium Alloy

Processing : Pressure Die Casting

Application : Automobile, Electrical, Industrial Machinery

Surface : Other, Polished/Smooth Finish

Automotive Part Aluminium Die Casting

Price Range 200.00 - 500.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, Aluminium Alloy

Processing : Die Casting

Application : Automotive Part

Surface : Other, Smooth, Corrosion Resistant Finish

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry