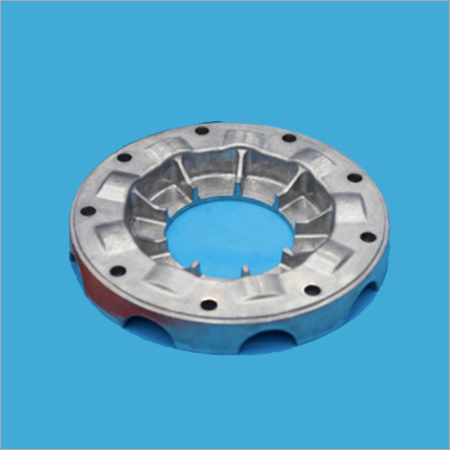

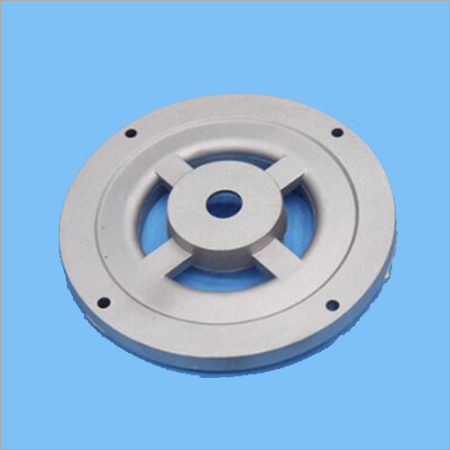

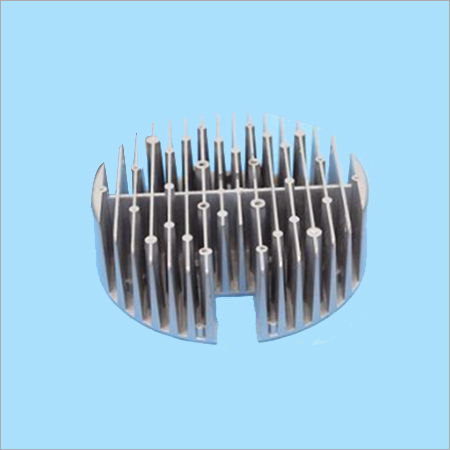

Aluminium Pressure Die Casting

Aluminium Pressure Die Casting Specification

- Material

- Aluminium Alloy

- Application

- Automobile, Electrical, Industrial Machinery

- Processing

- Pressure Die Casting

- Surface

- Polished/Smooth Finish

- Machining Type

- CNC, Milling, Drilling

- Tolerance

- ±0.02 mm

- Production Capacity

- 10000 Pieces/Month

- Weight

- 150 g to 5 Kg

- Colour

- Silver/Grey

- Mould Type

- Permanent Mold

- Shape

- Customized

- Casting Temperature

- 600°C - 700°C

- Hardness

- 60-80 HRB

- Corrosion Resistance

- High

Aluminium Pressure Die Casting Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 2 Pieces Per Day

- Delivery Time

- 2 - 10 Days

About Aluminium Pressure Die Casting

Our high-pressure die-casting components are manufactured using the latest and highly efficient HMT-BHULER make machines with capacity range from 80 tons to 1000 tons. We manufacture a wide array of aluminium and zinc die-castings.

We can deliver all kinds of complicated castings and components ranging from 5 grams to 9 Kgs with our ultramodern high-pressure casting technique. Our expertise lies in customizing components as per the specific requirements of the client.

With state-of-the-art technology; like automatic temperature control, we ensure utmost quality and precision during manufacturing the castings to guarantee efficiency, utility and safety.

Precision Engineering for Diverse Industries

Aluminium pressure die castings are meticulously engineered to deliver high tolerance and consistent performance across several industries. Their customizable shape and smooth finish make them highly sought after in the automobile, electrical, and industrial machinery sectors. With advanced CNC machining, each part maintains exact specifications and improved surface quality.

Superior Material and Finish

Constructed from quality aluminium alloy, these castings offer substantial hardness (60-80 HRB) and enhanced corrosion resistance. The polished silver or grey finish ensures both durability and aesthetic appeal, making them reliable for demanding environments and prolonged use.

High-Volume Manufacturing Capabilities

With a monthly production capacity of up to 10,000 pieces, our facility is equipped to fulfill bulk orders quickly and efficiently. Sourcing from India, clients benefit from rigorous quality standards and timely exports, suited for manufacturers, suppliers, and end-users worldwide.

FAQs of Aluminium Pressure Die Casting:

Q: How are aluminium pressure die castings manufactured using permanent molds?

A: Aluminium pressure die castings are produced by injecting melted aluminium alloy into permanent steel molds at temperatures between 600C and 700C. This method ensures repeatable quality, precise tolerances, and a consistent, smooth surface finish.Q: What are the main benefits of using high-corrosion resistant aluminium die castings?

A: These castings provide excellent durability against harsh environmental conditions, reducing the risk of rust and wear. Their high corrosion resistance makes them ideal for automotive, electrical, and industrial machinery applications where longevity is critical.Q: Where can customized aluminium castings be applied?

A: Customized aluminium pressure die castings are used in automobiles, electrical equipment, and industrial machinery, meeting specific design and performance requirements for diverse mechanical and electrical uses.Q: What processes are involved after die casting for surface refinement?

A: After casting, components undergo CNC machining, including milling and drilling, to achieve tight tolerance and detailed features. Polishing further improves the surface finish, ensuring parts meet both aesthetic and functional standards.Q: How does consistent tolerance contribute to product quality?

A: A tight tolerance of 0.02 mm ensures each casting conforms precisely to specifications, resulting in reliable assembly, enhanced fit, and reduced need for post-production adjustmentsespecially important in high-performance applications.Q: When should aluminium pressure die castings be chosen over other manufacturing methods?

A: These castings are preferred when high strength, precise dimensions, customized shapes, fast production turnaround, and corrosion resistance are required, particularly for medium to large batch orders.Q: What is the typical production capacity and delivery availability from your facility in India?

A: Our facility can supply up to 10,000 aluminium pressure die castings per month, with timely global export arrangements for manufacturers, suppliers, and clients seeking bulk or customized solutions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Die Casting Category

Aluminium Gravity Die Casting

Price Range 200.00 - 500.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Aluminum

Industrial Component Aluminium Pressure Die Casting

Price Range 200.00 - 500.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, Aluminium

Surface : Other, Smooth Finish, As Cast or Custom Surface Treatment

Application : Industrial Component Manufacturing, Automotive, Machinery Parts

Processing : Pressure Die Casting

Aluminium Pulley Die Casting

Price Range 200.00 - 500.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, Aluminium

Surface : Other, Natural, Sandblasted, Shot Blasted

Application : Industrial Machinery, Automotive, Pulley Systems

Processing : Die Casting

Automotive Part Aluminium Die Casting

Price Range 200.00 - 500.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, Aluminium Alloy

Surface : Other, Smooth, Corrosion Resistant Finish

Application : Automotive Part

Processing : Die Casting

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry