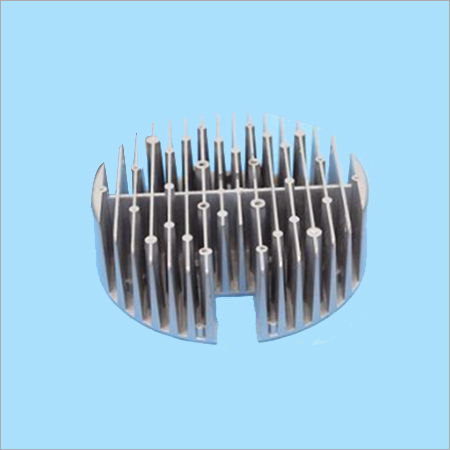

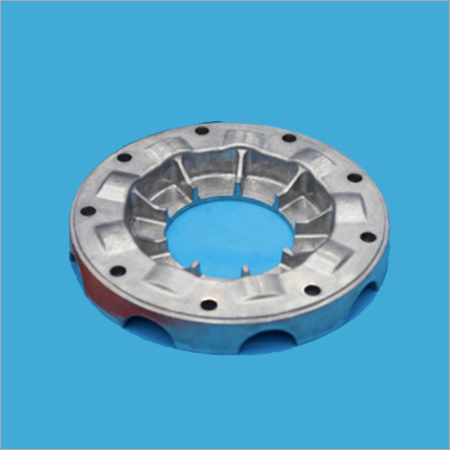

Aluminium Automotive Die Casting

MOQ : 500 Pieces

Aluminium Automotive Die Casting Specification

- Material

- Aluminium

- Application

- Automotive Components

- Processing

- Die Casting

- Surface

- Smooth / Polished

- Machining Type

- Precision CNC Machining

- Part Size Range

- Small to medium

- Corrosion Resistance

- Excellent

- Casting Weight

- Up to 10 kg

- Production Capacity

- Bulk and prototype

- Tolerance

- ±0.02 mm

- Shape Complexity

- Custom and intricate designs

- Heat Treatment

- Optional

- Strength

- High structural integrity

- Finishing Options

- Anodizing, Powder Coating, Painting

- Standard

- ISO 8062 (Casting tolerances)

Aluminium Automotive Die Casting Trade Information

- Minimum Order Quantity

- 500 Pieces

- Supply Ability

- 2 Pieces Per Day

- Delivery Time

- 2 - 10 Days

About Aluminium Automotive Die Casting

Unlock unmatchable precision and performance with our splendiferous Aluminium Automotive Die Casting solutions. Engineered to glorious standards with ISO 8062 compliance and competitive pricing, our casts offer intricately custom shapes, high structural integrity, and excellent corrosion resistance. With a tolerance of 0.02 mm and casting weights up to 10 kg, these components embody quality and reliability. Available finishing options include anodizing, powder coating, and painting. Ideal for both prototyping and bulk production, we deliver each part with glorious accuracy, making us a top exporter, manufacturer, and supplier from India.

Aluminium Die Casting Versatile Automotive Use

Our aluminium automotive die casting is integral to structural and functional automotive components, ensuring durability and optimal performance. Designed for varied use typesranging from chassis parts to intricate engine mountsthese die-cast elements serve critical applications within the automotive industry. Suitable for both prototype development and high-volume site applications, our casts are tailored for custom design requirements, delivering efficiency and strength where its needed most.

Aluminium Automotive Die Casting Export Markets & Delivery

We proudly offer our aluminium die castings to global main export markets including Europe, North America, and Asia. Each order is carefully handed over from our ISO-certified facility in India, shipped from leading Indian FOB ports. To ensure product integrity, every item is securely packed in export-grade wooden crates or customized packaging, ready to be safely handed over to clients worldwide. Trust us to offer excellence in every delivery.

Aluminium Die Casting Versatile Automotive Use

Our aluminium automotive die casting is integral to structural and functional automotive components, ensuring durability and optimal performance. Designed for varied use typesranging from chassis parts to intricate engine mountsthese die-cast elements serve critical applications within the automotive industry. Suitable for both prototype development and high-volume site applications, our casts are tailored for custom design requirements, delivering efficiency and strength where its needed most.

Aluminium Automotive Die Casting Export Markets & Delivery

We proudly offer our aluminium die castings to global main export markets including Europe, North America, and Asia. Each order is carefully handed over from our ISO-certified facility in India, shipped from leading Indian FOB ports. To ensure product integrity, every item is securely packed in export-grade wooden crates or customized packaging, ready to be safely handed over to clients worldwide. Trust us to offer excellence in every delivery.

FAQs of Aluminium Automotive Die Casting:

Q: How does aluminium automotive die casting achieve such precise tolerances?

A: Aluminium automotive die casting utilizes high-pressure techniques and advanced molds, allowing for dimensional tolerances as fine as 0.02 mm. Precision CNC machining further refines the parts to guarantee accuracy and reliability for critical automotive applications.Q: What are the primary applications for these die-cast aluminium components?

A: These die-cast components are widely used in automobile manufacturing for engine mounts, brackets, housings, and a range of structural or functional parts. Their high strength and corrosion resistance make them ideal for demanding automotive environments.Q: When should optional heat treatment be considered for die-cast parts?

A: Heat treatment is recommended when enhanced mechanical properties, increased strength, or specific hardness levels are required in the final automotive part. This is typically determined by the applications stress and load-bearing requirements.Q: Where are these aluminium die castings produced and exported from?

A: All our aluminium automotive die castings are produced in our state-of-the-art facility in India and exported globally, primarily to Europe, North America, and Asia via major Indian FOB ports.Q: What finishing options do you offer for aluminium die castings?

A: We provide multiple premium surface finishing options, including anodizing, powder coating, and precision painting, each delivering excellent aesthetic appeal and robust protection against corrosion.Q: How does the die casting process ensure high structural integrity?

A: The pressure-based die casting process produces parts with fine grain structure and minimal porosity, resulting in unmatchable structural integrity and superior strength for automotive applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Aluminium Die Casting Category

Aluminium Gravity Die Casting

Price Range 200.00 - 500.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Aluminum

Aluminium Pressure Die Casting

Price Range 200.00 - 500.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, Aluminium Alloy

Surface : Other, Polished/Smooth Finish

Machining Type : CNC, Milling, Drilling

Processing : Pressure Die Casting

Industrial Component Aluminium Pressure Die Casting

Price Range 200.00 - 500.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Material : Other, Aluminium

Surface : Other, Smooth Finish, As Cast or Custom Surface Treatment

Machining Type : CNC Machining, Traditional Machining

Processing : Pressure Die Casting

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry