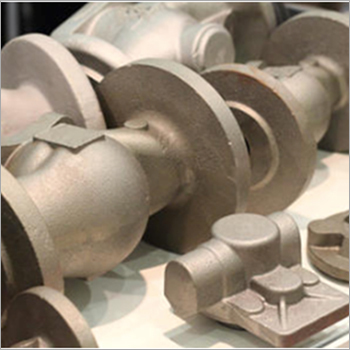

Sand Die Casting

Product Details:

- Product Type Aluminium Castings

- Material Aluminum

- Application sand casting

- Processing Casting

- Machining Type CNC MACHINING

- Click to View more

Sand Die Casting Price And Quantity

- 5 Piece

- 500 INR/Piece

Sand Die Casting Product Specifications

- sand casting

- Casting

- Aluminium Castings

- Aluminum

- CNC MACHINING

Sand Die Casting Trade Information

- Cash on Delivery (COD) Letter of Credit at Sight (Sight L/C) Letter of Credit (L/C) Cash Against Delivery (CAD) Telegraphic Transfer (T/T)

- 2 Piece Per Week

- 2 Week

- All India

Product Description

Sunita Biotech, we produce of quality aluminium sand castings every year, manufacturing large quantities of small castings or large aluminium sand castings up to 80 kg in weight.

Businesses use our services because of our experience and expertise. Our key strengths include:

- We continually invest in our facilities, technologies and staff.

- Our focus is primarily on providing excellent customer service. Our customers use us again and again.

- We can provide full project support from prototype development, pattern making right through to supplying fully machined castings.

Casting by sand is a highly successful and cost-effective process for small batch parts.

The pure asset of the moulds created means that a much greater weight of metal can be used, allowing for the casting of complicated parts that might otherwise have been fabricated from individual parts.

Moulds can be created for a lower initial setup cost compared to and other casting methods.

Silica sand is mechanically mixed with binders to produce a hardened sand mould. Our moulding sand is a special blend of thermally reclaimed, mechanically processed and virgin silica sand.

We then follow a multiple step process to produce a two part mould, a top and bottom, termed a Cope and Drag:

- Fill each half moulding box with sand to create the mould.

- Strip or remove the pattern from the two mould halves and put together.

- Fill mould with quality molten metal.

- Allow the metal to cool.

- After metal has solidified and cooled, break the sand away from casting and finish processing the casting.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Sand Die Casting' category

|

SUNITA BIOTECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry